HYDRAULIC ROCK BREAKER SPARES

Hydraulic rock breakers play a vital role in industries like mining, construction, and demolition, breaking through tough materials such as rock and concrete. Regular maintenance and the use of high-quality parts are essential to ensure their efficiency and longevity.

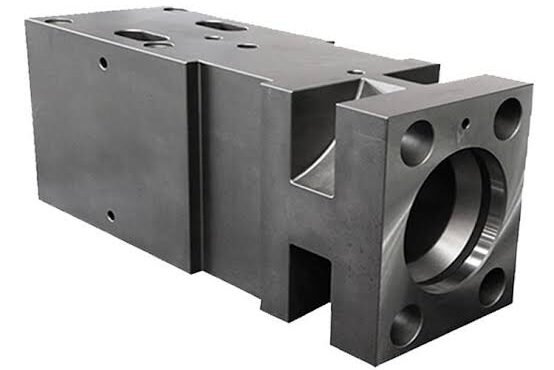

Hydraulic Rock Breaker Spares

For demanding excavation and demolition tasks, hydraulic rock breakers are essential tools. Proper maintenance with the right spare parts is key to ensuring their efficiency and extending their lifespan. Using genuine, high-quality replacement parts, combined with regular upkeep, will keep your hydraulic breaker running safely and effectively while delivering the power needed for even the toughest jobs.

This guide covers the essential spare parts for hydraulic rock breakers, their functions, and why using authentic components is so important.

Spare Parts for Hydraulic Rock Breakers

Chisel/Bits

- Description: The chisel or tool bit is the primary working part of a rock breaker. It directly contacts the material being broken, transferring the energy from the hammer to the target.

- Types: Common types include moil points, chisels, blunt tips, and cone points, each designed for specific applications.

- Importance: Regular replacement of worn-out chisels ensures efficient operation and prevents damage to other components.

Pistons

- Description: The piston is responsible for generating the impact force by moving up and down within the cylinder, striking the chisel.

- Importance: A well-maintained piston is essential for delivering consistent power. Damaged or worn pistons can reduce performance and lead to costly repairs.

Bushings

- Description: Bushings are cylindrical components that support and guide the movement of the chisel within the breaker housing. They reduce friction and wear between the chisel and the housing.

- Importance: Worn bushings can cause excessive movement of the chisel, leading to misalignment and potential damage to the piston and housing.

Seals and Seal Kits

- Description: Seals prevent hydraulic fluid from leaking out of the breaker and keep contaminants from entering the system. Seal kits typically include O-rings, dust seals, and rod seals.

- Importance: Proper sealing is crucial for maintaining hydraulic pressure and preventing contamination. Regular inspection and replacement of seals help avoid leaks and ensure efficient operation.

Tie Rods

- Description: Tie rods hold the main body components of the hydraulic breaker together, maintaining structural integrity under high-impact conditions.

- Importance: Broken or worn tie rods can compromise the structural stability of the breaker, leading to equipment failure. Regular inspection and replacement are critical for safety and performance.

Back Head

- Description: The back head is part of the hydraulic breaker that contains nitrogen gas, which helps to provide additional impact energy during operation.

- Importance: Proper maintenance of the back head ensures optimal energy transfer and overall efficiency. Any damage or leaks in this component can significantly affect the breaker’s performance.

Side Bolts

- Description: Side bolts help hold the outer casing of the hydraulic breaker together, securing the housing and internal components.

- Importance: Regular inspection of side bolts is necessary to prevent loosening or breakage, which could lead to damage to the breaker’s body or internal parts.