AUTOMATIC WELDING & LINE BORING

Two essential methods for maintaining and repairing heavy machinery and equipment are automatic welding and line boring. These procedures are necessary to guarantee the longevity and best possible operation of machinery by returning worn or damaged parts to their original standards.

Automatic Welding & Line Boring

Modern techniques such as automatic welding and line boring are vital for the maintenance and repair of large machinery. By understanding their applications, benefits, and best practices, operators can ensure their equipment runs efficiently, reducing downtime and boosting production. These processes are key to maintaining the reliability and performance of industrial machinery, whether it’s precise line boring or repairing damaged surfaces with precision welding.

Benefits of Automatic Welding & Line Boring

Consistency and Quality

Automated systems ensure uniform welds with minimal defects, reducing the need for rework.

Increased Productivity

Automatic welding significantly speeds up the welding process, reducing downtime and increasing output.

Reduced Labor Costs

Automation reduces the need for skilled welders, lowering labor costs and minimizing the risk of human error.

Enhanced Safety

Automated systems remove operators from hazardous environments, reducing the risk of injury from fumes, heat, and sparks.

Types of Automatic Welding

Submerged Arc Welding (SAW)

A process in which the weld is shielded by a layer of flux to protect it from atmospheric contamination, SAW is commonly used for welding thick materials and large components, providing deep penetration and high deposition rates.

Gas Metal Arc Welding (GMAW)

Also known as MIG welding, GMAW utilizes a continuous wire feed and a shielding gas to protect the weld pool. It is ideal for welding thin to medium-thickness materials and is commonly used in automotive and structural applications.

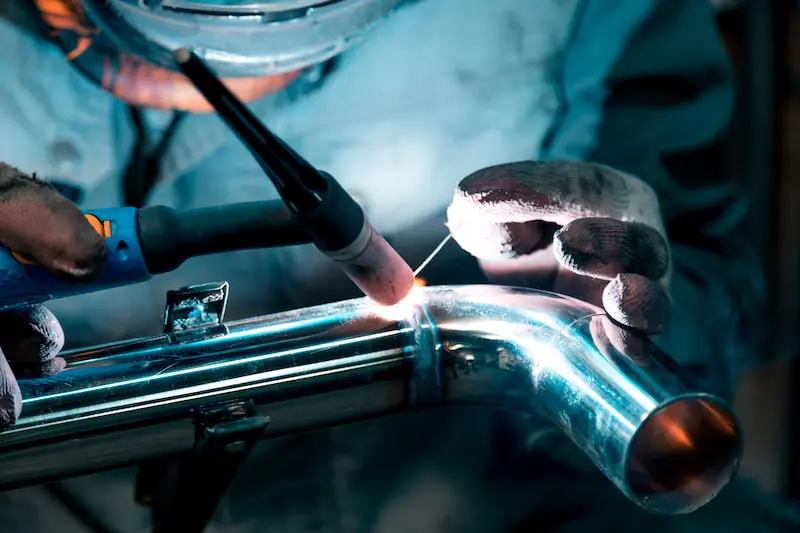

Tungsten Inert Gas (TIG) Welding

TIG welding employs a non-consumable tungsten electrode and shielding gas, offering precise control over the welding process. It is ideal for welding thin materials and applications that require high-quality welds.

Flux-Cored Arc Welding (FCAW)

Similar to MIG welding, FCAW uses a tubular wire filled with flux. It is effective for welding thicker materials, offering good penetration and strength.