ALL EXCAVATOR RELATED SPARE PARTS

Useful and adaptable equipment, excavators are employed in many different sectors of the economy, such as mining, agriculture, and construction. They carry out a variety of duties, including demolition, grading, lifting, and digging. Having access to a wide range of spare parts is essential to maintaining excavators at maximum performance and reducing downtime.

All Excavator Related Spare Parts

To keep an excavator running at peak efficiency, it’s essential to have access to high quality spare parts and a solid understanding of its various components. Each part whether it’s the engine, hydraulics, undercarriage, or specialized attachments is critical to the overall performance and effectiveness of the machine. By investing in genuine spare parts and following a proactive maintenance plan, operators can enhance the durability, safety, and reliability of their excavators. This leads to smoother operations and reduced downtime, especially in demanding working conditions.

Main Categories of Excavator Spare Parts

Engine Parts

- Cylinder Heads: Essential for the combustion process, these parts seal the top of the engine cylinders and house components like valves and spark plugs.

- Pistons and Rings: Critical for the compression of fuel and air mixture within the engine cylinders.

- Fuel Injectors: Deliver fuel into the engine cylinders in a precise manner for efficient combustion.

- Turbochargers: Enhance engine power and efficiency by forcing extra air into the combustion chamber.

- Filters (Air, Oil, Fuel): Prevent contaminants from entering the engine, hydraulic system, and fuel lines, thereby protecting the engine from damage.

- Cooling Systems: Include radiators, water pumps, and thermostats, essential for maintaining optimal engine temperature.

Hydraulic Parts

- Hydraulic Pumps: Provide the necessary power to move the excavator’s arm, boom, and bucket. They are critical for lifting and digging operations.

- Hydraulic Cylinders: Convert hydraulic fluid pressure into mechanical force to move the boom, arm, and other attachments.

- Hydraulic Hoses and Fittings: Transport hydraulic fluid between different parts of the system, such as pumps, cylinders, and control valves.

- Control Valves: Regulate the flow of hydraulic fluid to various parts of the excavator, ensuring precise movement and operation.

- Hydraulic Filters: Remove contaminants from the hydraulic fluid to prevent damage to components and ensure smooth operation.

Undercarriage Parts

- Track Chains: Provide traction and mobility on various terrains. They are essential for the excavator’s stability and movement.

- Track Rollers: Support the weight of the excavator and enable smooth movement along the track chains.

- Idlers and Tensioners: Maintain proper tension in the track chains and guide them smoothly over the rollers.

- Sprockets: Drive the track chains, enabling the excavator to move forward or backward.

- Track Shoes and Pads: Attach to the track chains and provide ground contact, offering grip and stability on different surfaces.

Electrical Parts

- Batteries: Provide the necessary power to start the engine and operate electronic systems.

- Alternators: Charge the battery and power the electrical systems while the engine is running.

- Control Panels: Interface between the operator and the machine, providing information and controls for various functions.

- Wiring Harnesses: Connect different electrical components and transmit signals throughout the excavator.

- Sensors and Switches: Monitor various aspects of the machine’s performance, such as temperature, pressure, and position, and relay this information to the control system.

Cabin and Control Parts

- Seats: Provide comfort and support for the operator during extended periods of use.

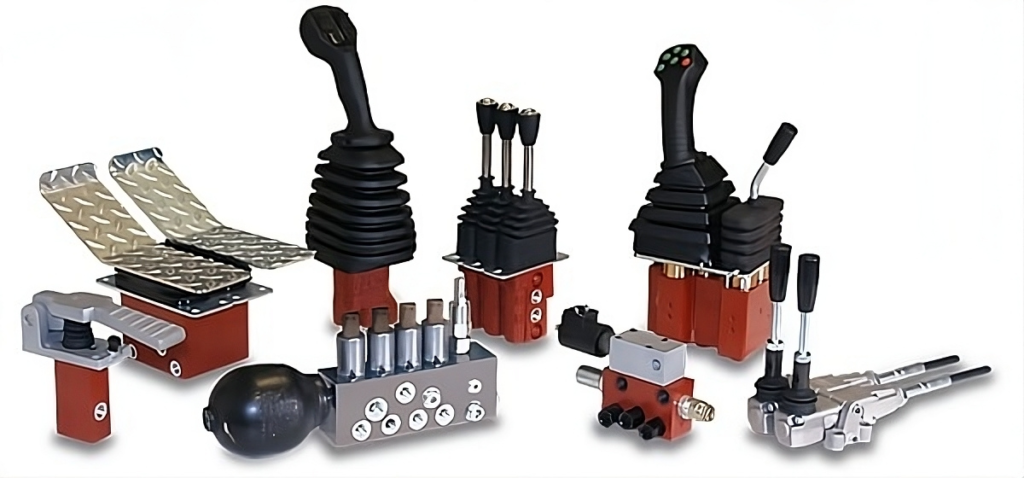

- Joysticks and Control Levers: Allow the operator to control the movement of the excavator’s boom, arm, and bucket.

- Display Panels: Show important information like fuel levels, engine temperature, and operational status.

- Air Conditioning and Heating Systems: Maintain a comfortable environment for the operator, especially in extreme weather conditions.

- Cabin Glass and Doors: Protect the operator from external elements and provide visibility during operation.

Attachment Parts

- Buckets: Available in various shapes and sizes for different tasks such as digging, grading, and material handling.

- Teeth and Adapters: Attach to the edge of the bucket to enhance digging efficiency and durability.

- Quick Couplers: Allow for rapid attachment and detachment of different tools and accessories, increasing versatility.

- Thumbs and Grapples: Used for handling irregular materials such as rocks, logs, and debris.

- Hammers and Breakers: Attachments for breaking concrete, rocks, and other hard materials during demolition tasks.

Swing System Parts

- Swing Motors: Drive the rotation of the excavator’s upper structure, allowing it to pivot.

- Swing Bearings: Support the upper structure and enable smooth rotation with minimal friction.

- Swing Gearboxes: Transmit power from the swing motor to the swing bearing, enabling controlled movement.

Drive and Transmission Parts

- Final Drives: Transmit power from the hydraulic motors to the track chains, enabling movement.

- Travel Motors: Provide the necessary force for moving the excavator on its tracks.

- Transmission Gears: Ensure smooth and efficient power transfer between different components of the drive system.

Cooling System Parts

- Radiators: Dissipate heat from the engine coolant, maintaining optimal engine temperature.

- Cooling Fans: Increase airflow through the radiator, enhancing cooling efficiency.

- Water Pumps: Circulate coolant through the engine and radiator, preventing overheating.

Lubrication and Sealing Parts

- Seals and Gaskets: Prevent leaks in various systems, such as the engine, hydraulic system, and gearboxes.

- Grease Fittings: Allow for regular lubrication of moving parts, reducing wear and tear.

- O-Rings: Provide sealing between different parts to prevent fluid leaks and contamination.