ALL KINDS OF LATHE WORKS

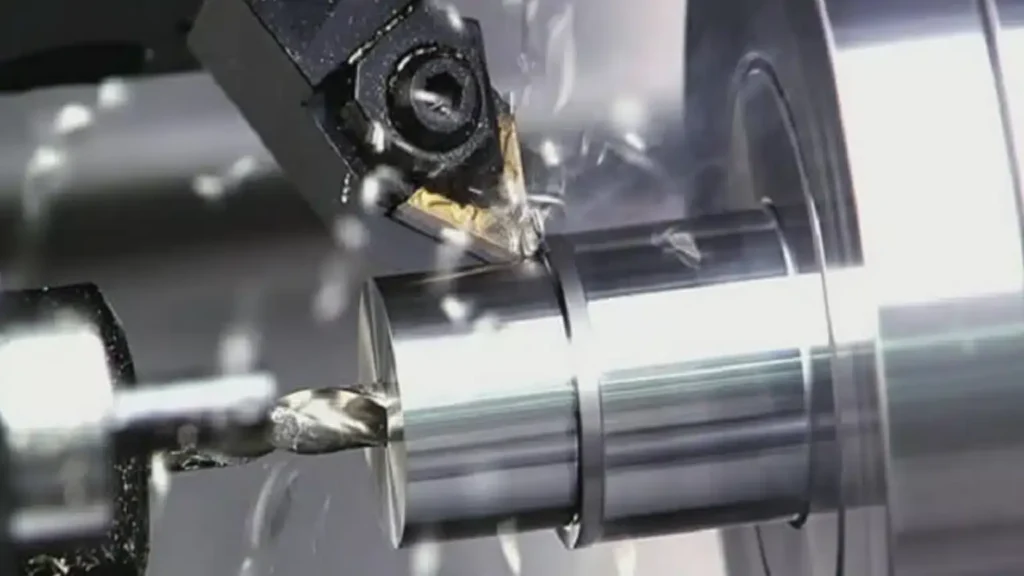

Lathe work is an essential aspect of precision machining used in numerous industries to shape and finish metal, wood, and plastic parts. Lathes are versatile machines that can perform a wide range of operations, including turning, facing, threading, drilling, boring, and knurling.

All Kinds Of Lathe Work

A key component of machining is lathe work, which provides accuracy, adaptability, and efficiency in the production of a variety of components. Lathes are vital tools in many industries, used for tasks including threading, turning, drilling, and knurling. Manufacturers and craftsmen can increase overall productivity, minimize downtime, and produce high-quality outcomes by knowing the various kinds of lathe operations and adhering to best practices.

Precision machining requires lathe work, which is crucial for shaping and finishing metal, wood, and plastic components in a variety of industries. Lathes are multipurpose tools that are capable of a variety of tasks, such as threading, drilling, boring, knurling, facing, and turning. An overview of the various kinds of lathe work, their uses, and the advantages they bring to the processes of manufacture and maintenance are given in this handbook.

Types of Lathe Work

Turning

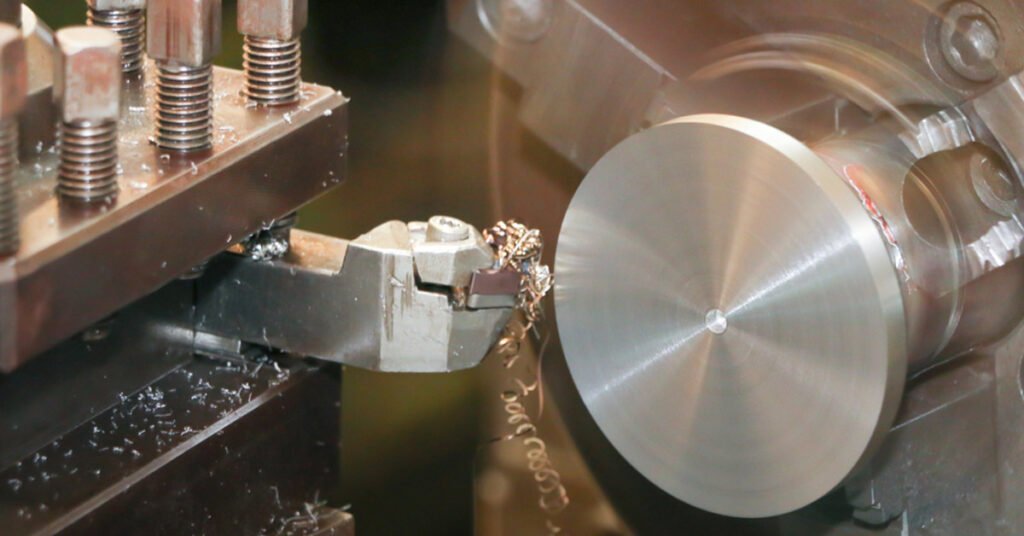

- External Turning: Involves reducing the diameter of a cylindrical workpiece to achieve the desired shape and size. It is commonly used to create shafts, pins, and cylindrical components.

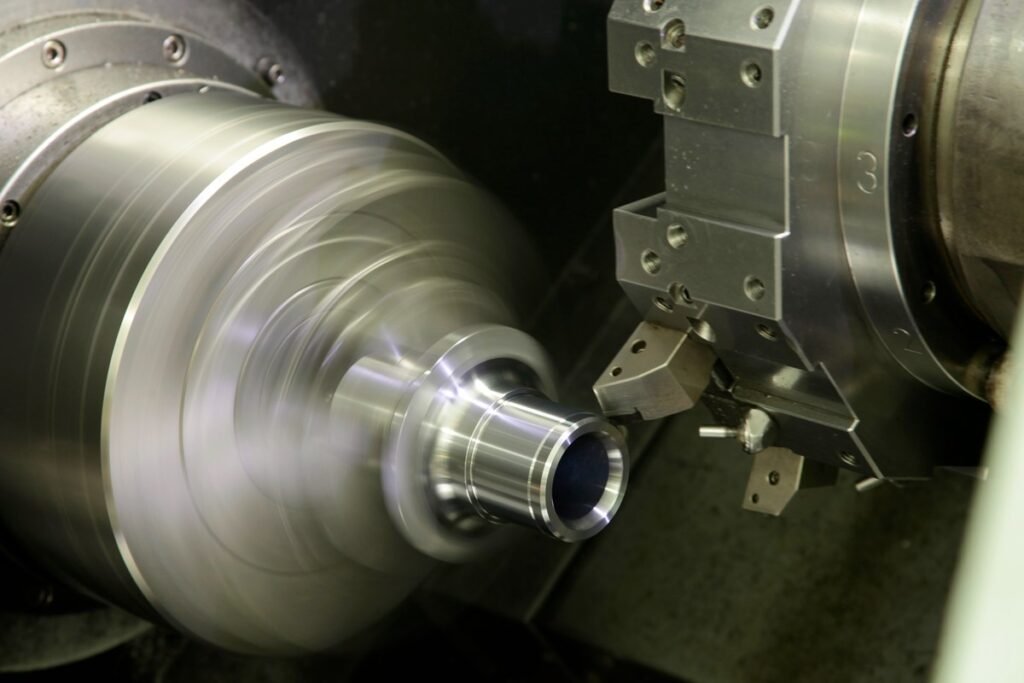

- Internal Turning (Boring): Used to enlarge or finish the inner diameter of a pre-drilled hole, improving precision and surface finish.

Facing

- External Turning: Involves reducing the diameter of a cylindrical workpiece to achieve the desired shape and size. It is commonly used to create shafts, pins, and cylindrical components.

- Internal Turning (Boring): Used to enlarge or finish the inner diameter of a pre-drilled hole, improving precision and surface finish.

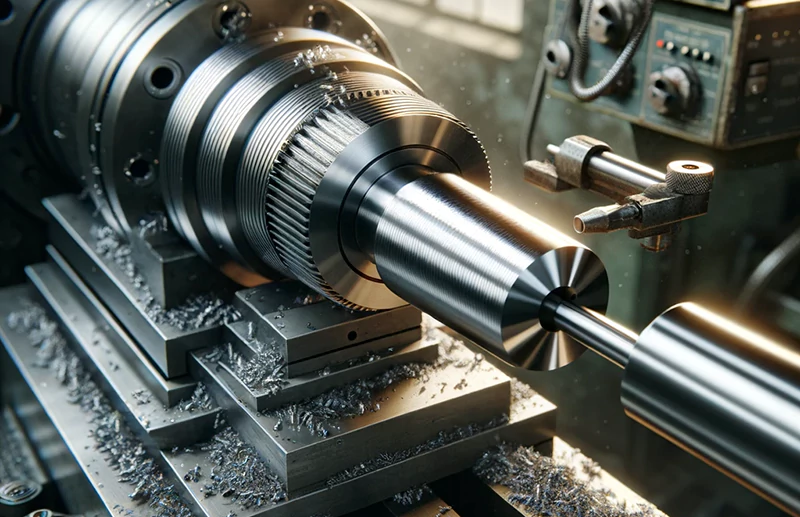

Threading

Used to cut threads on the internal or external surface of a cylindrical workpiece. This process is critical for creating screw threads, bolts, and other fasteners.

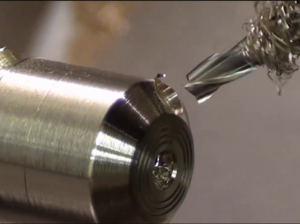

Drilling and Boring

- Drilling: A lathe can be used to drill precise holes in a workpiece using a drill bit held in the tailstock.

- Boring: Expands an existing hole to a specific size and improves its accuracy.

Knurling

A process that produces a textured pattern on the surface of the workpiece, providing a better grip. This is commonly used on tool handles and knobs.

Parting (Cutting Off)

Involves cutting a part of the workpiece from the main bar or rod using a parting tool. This operation is useful for creating washers, spacers, and other small components.

Grooving

Used to cut grooves of various shapes and depths on the internal or external surface of the workpiece. Grooving is essential for creating snap rings, sealing grooves, and other features.

Taper Turning

Involves creating a tapered surface where the diameter of the workpiece gradually changes from one end to the other. This is commonly used for creating conical components such as pins and machine spindles.

Form Turning

A process used to create complex shapes and profiles on the surface of the workpiece. It involves using a specially shaped cutting tool to achieve the desired contour.

Eccentric Turning

Involves turning a workpiece that has multiple axes of rotation. This process is used to create components like camshafts and crankshafts.