BOSCH PUMP CALIBRATION

Engine performance, fuel efficiency, and emissions are all directly impacted by accurate fuel distribution, which is made possible by Bosch pumps, especially those found in diesel engines. To keep these pumps functioning and long-lasting, proper calibration is necessary.

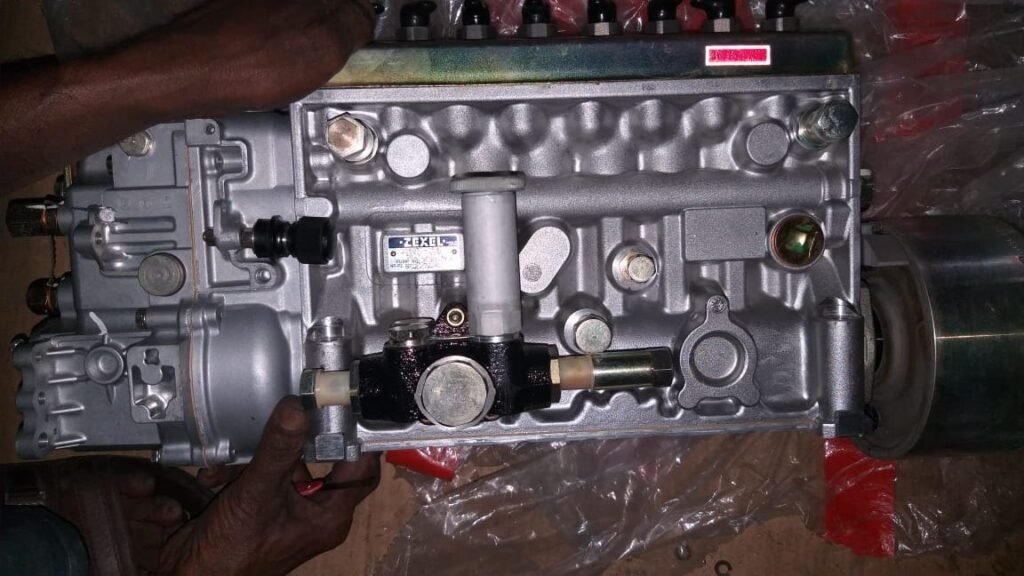

Bosch Pump Calibration

A crucial maintenance step that guarantees the effective and dependable operation of diesel engines is the calibration of Bosch pumps. Engine power, fuel efficiency, and emissions are all optimized by calibration, which involves precisely modifying the fuel delivery parameters. For diesel engines to operate efficiently and effectively, competent Bosch pump calibration is necessary, whether for maintenance, repair, or regulatory compliance.

The Bosch Pump Calibration Process

A regulated atmosphere, specialized tools, and technical know-how are needed for calibrating a Bosch pump. The general stages for calibrating a Bosch pump are as follows:

Preparation

Before starting the calibration process, ensure the pump is clean and in good working condition. Check for any signs of wear or damage and replace any defective parts.

Mounting the Pump on a Test Bench

The pump is mounted on a dedicated calibration test bench equipped with precision measuring instruments. The test bench simulates engine conditions, allowing for accurate calibration.

Setting Injection Timing

The first step in calibration is adjusting the fuel injection timing. This involves setting the pump to deliver fuel to the engine cylinder at the correct moment in the combustion cycle.

Adjusting Fuel Delivery Quantity

The amount of fuel delivered to each cylinder must be precisely measured and adjusted. This is done by altering the position of the control rack (in inline pumps) or the rotor head (in rotary pumps).

Pressure Testing

The fuel delivery pressure is tested and adjusted to ensure it meets the engine's requirements. This step is crucial for achieving optimal atomization and combustion of the fuel.

Fine-Tuning

After the initial adjustments, the pump is fine-tuned to ensure it performs consistently across different operating conditions. This may involve minor tweaks to injection timing, quantity, and pressure.

Final Testing and Verification

The calibrated pump undergoes a series of tests to verify its performance. This includes checking for uniform fuel delivery, proper pressure levels, and consistent operation under simulated engine loads.

Documentation

The calibration settings and results are documented for future reference. This information is essential for maintenance and troubleshooting purposes.