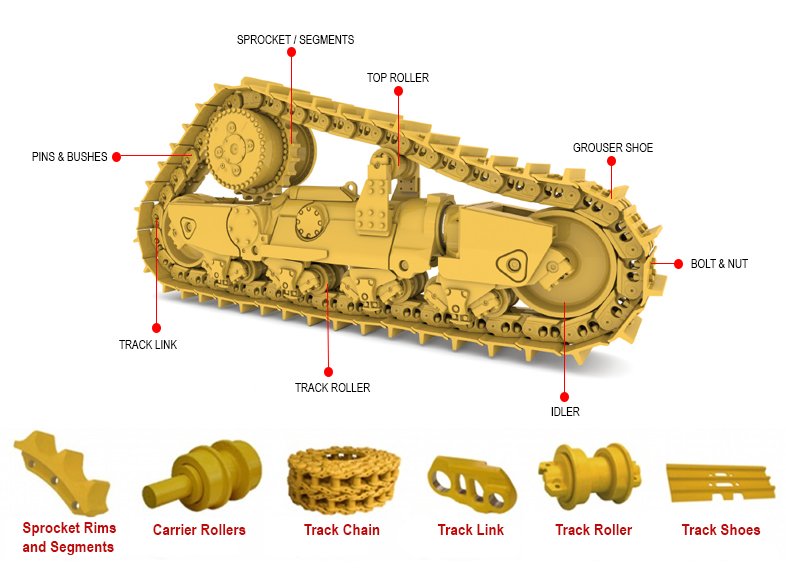

UNDERCARRIAGE PARTS

An excavator’s undercarriage is a vital part that gives the machine support, mobility, and stability. It is made up of multiple components that cooperate to enable the excavator to navigate across different terrains with efficiency. An excavator’s longevity and optimum performance depend on timely replacement of undercarriage parts and proper maintenance.

Undercarriage Parts

An excavator’s undercarriage plays a critical role in determining its efficiency, performance, and safety. Operators and fleet managers need to understand the different parts, how they work, and how important maintenance is. Regular inspections can be prioritized to maximize the excavator’s lifespan and effectiveness, assuring top performance across a variety of working situations. High-quality replacement components should also be used.

Importance of Maintaining Undercarriage Parts

Performance and Efficiency

Proper upkeep of the excavator's undercarriage components guarantees excellent performance and seamless mobility. Fuel consumption can rise and efficiency can be decreased.

Cost Savings

Major breakdowns can be avoided by routine undercarriage part examination and prompt replacement, which lowers maintenance costs and downtime.

Extended Lifespan

Keeping the excavator's undercarriage in good shape increases its lifespan. Preventing wear and tear on machine parts helps ensure the machine's structural integrity.

Improved Traction and Stability

Sustaining the undercarriage improves stability and traction, particularly in difficult terrain. This is essential for operations requiring control, precision.

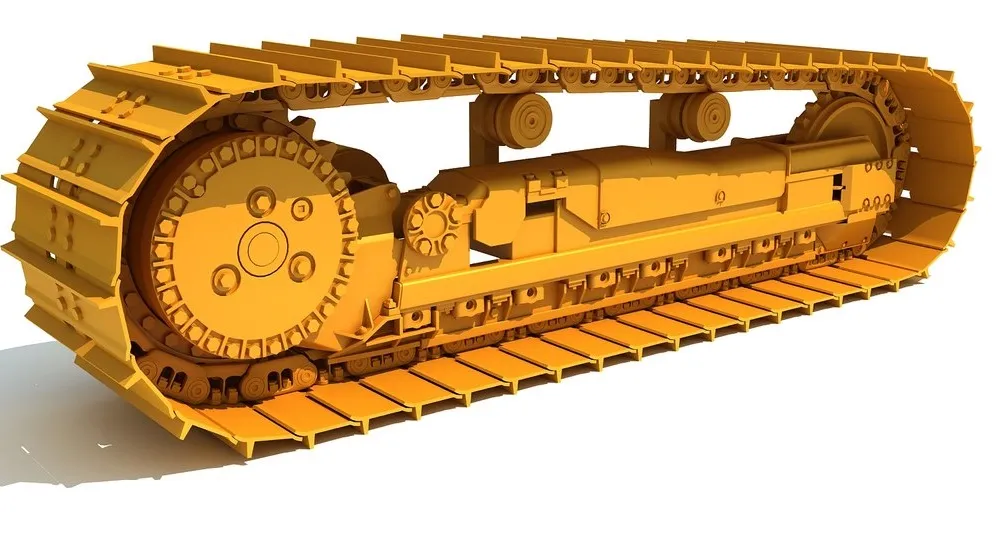

Components of the Undercarriage

Track Chains

- Function: Track chains provide traction and support the weight of the excavator. They allow the machine to move across soft or uneven surfaces where wheels might struggle.

- Types: Available in various configurations, including steel and rubber tracks, depending on the application and terrain.

Track Rollers

- Function: Track rollers support the track chains and allow for smooth movement over the ground. They help distribute the weight of the excavator evenly.

- Types: Include top rollers (located above the track) and bottom rollers (located beneath the track), both of which reduce friction and wear.

Idlers

- Function: Idlers are located at the front of the undercarriage and guide the track chain. They help maintain proper tension and alignment of the track.

- Types: Often equipped with a smooth surface to facilitate movement without causing excessive wear on the track.

Tensioners

- Function: Tensioners maintain the correct tension in the track chain, ensuring it fits snugly around the rollers and idlers. Proper tension is crucial for efficient operation and to prevent derailment.

- Types: Can be mechanical or hydraulic, depending on the excavator model.

Sprockets

- Function: Sprockets are the driving gears that engage with the track chain. They provide the necessary motion for the tracks to rotate and propel the excavator.

- Types: Available in various tooth configurations and sizes, suited to different track types.

Track Shoes

- Function: Track shoes are the individual segments of the track chain that come into contact with the ground. They provide grip and traction while protecting the track from wear.

- Types: Available in different widths and designs, including standard, wide, and claw-style shoes, depending on the application and soil conditions.

Track Frames

- Function: The track frame is the structure that houses all the undercarriage components. It provides support and stability for the entire machine.

- Types: Designed to withstand heavy loads and harsh conditions, often made from high-strength steel.

Link Assemblies

- Function: Link assemblies connect the individual track shoes together, forming the complete track chain. They provide flexibility and strength to the track system.

- Types: Available in various configurations, including single, double, or triple link designs.

Hydraulic Cylinders

- Function: Hydraulic cylinders in the undercarriage are responsible for adjusting the tension in the tracks and providing power for movement.

- Types: Can vary in size and capacity depending on the excavator’s specifications.

Suspension Systems

- Function: Some excavators are equipped with suspension systems in the undercarriage to absorb shocks and improve ride quality over rough terrain.

- Types: Include rubber or hydraulic suspension systems that enhance stability and operator comfort.